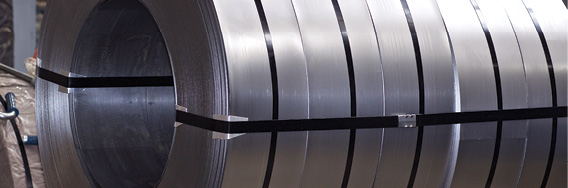

Raw material information:

Definition of galvanizing:

The importance of galvanizing:

The process of galvanizing the metal protects it from corrosion and damage as it gives it anti-corrosion properties and prevents the access of water and environmental factors to the iron layer, and the use of galvanized steel comes at a low cost compared to other materials that are not subject to rust such as expensive types of steel, aluminum and other materials, This is what makes many factories rely on the use of galvanized iron.

It should be noted that the galvanizing process appeared a very long time ago and was known to many human civilizations; However, it did not appear in the currently accepted form until the century before the last; Where a complete galvanizing process for metals was carried out by a French scientist, who subsequently obtained a patent, called (Stanislas Sorrell).

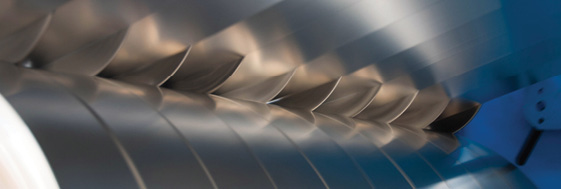

Production stages of metal cutters

Metal sectors.. depends on them

بمواصفات الجودة القياسية